Noztek, a leading supplier of extrusion equipment, has unveiled its latest innovation, the Infinity Print Bed Conveyor, which promises to revolutionise the field of robotic 3D printing.

Equipped with print and eject functionality, alongside continuous 45-degree angle printing, the system is capable of operating around the clock, producing thousands of components from a range of advanced materials, including Carbon, Kevlar composites, and specialised thermoplastics.

Steven Forster of Noztek commented: “We are delighted to unveil this innovative new product, which is set to be a game changer for robotic 3D printing.

“Ever since the release of the initial Noztek Pro in 2013, our company has undergone significant growth and established itself as a prominent player in the additive market. This latest product is another example of the way we pride ourselves on being one step ahead of the competition and the leading innovator of cutting-edge extrusion equipment.”

The Infinity Print Bed Conveyor’s heated bed allows multiple parts to be printed simultaneously, ensuring maximum utilisation of the print area. Once a print job is completed, the roller rotates half a turn to release the printed items efficiently, preparing the bed for the next production cycle. This automation streamlines workflows and minimises the need for manual intervention.

In addition, the roller conveyor acts as an infinity print bed, enabling the production of extremely long 3D prints. A robotic arm prints at a 45-degree angle, with the conveyor belt shifting by 1 degree after each layer, allowing for the creation of lengthy components limited only by the available workspace. By attaching support structures to one end of the conveyor, users can produce extended objects with exceptional precision.

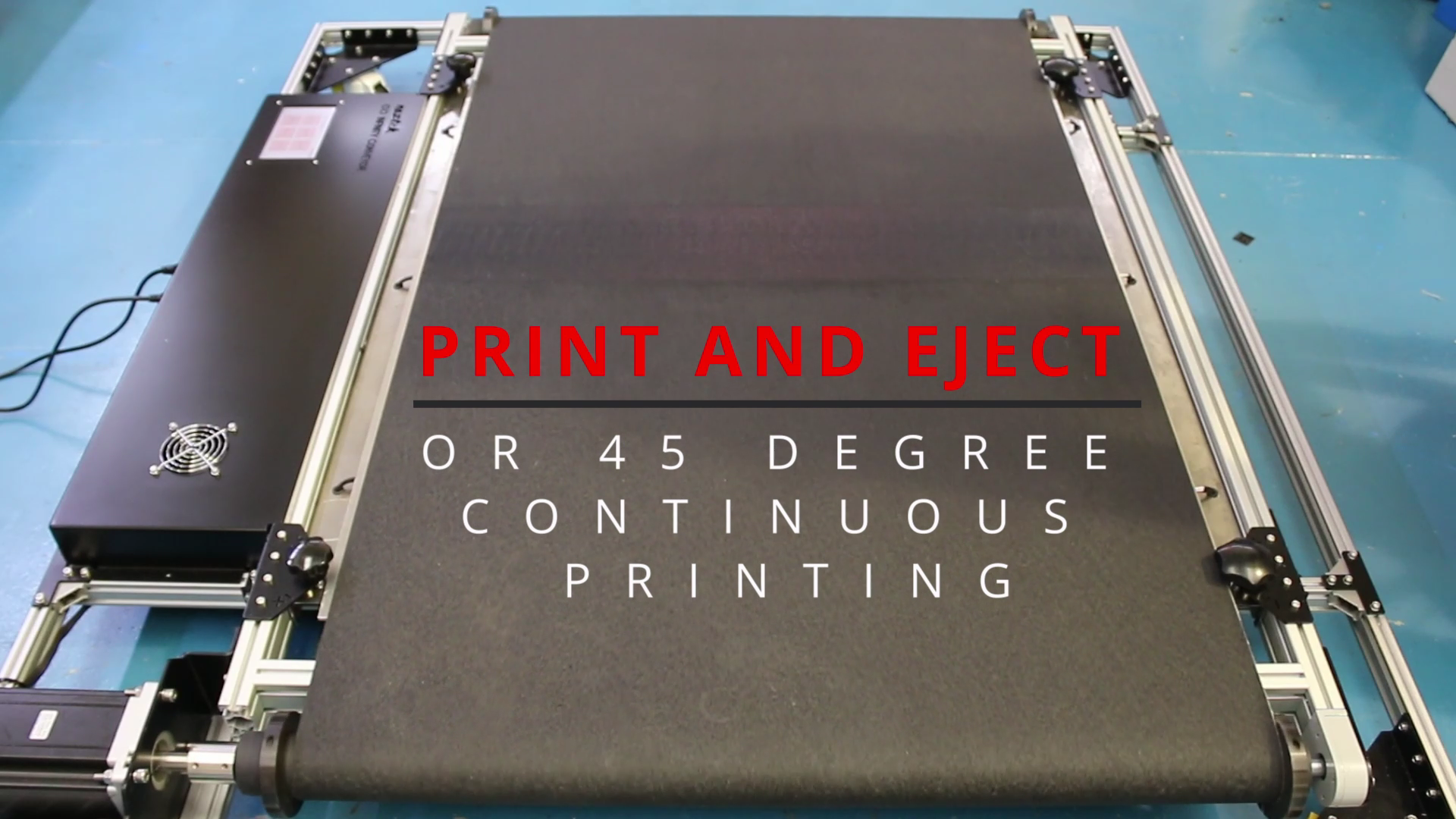

Designed with durability and precision, the roller conveyor’s structure includes an aluminium subframe and a 5mm steel support bed. Six independently mounted 750w heater panels ensure consistent and uniform heating throughout the printing process. The system is powered by a high-torque stepper motor and integrates seamlessly with the robot’s control panel via Ethernet/IP connectivity.

Measuring 1.5 metres in length and 1 metre in width, this cutting-edge roller conveyor combines robust construction with advanced functionality.

For further details on Noztek and the Infinity Print Bed Conveyor, visit noztek.com.